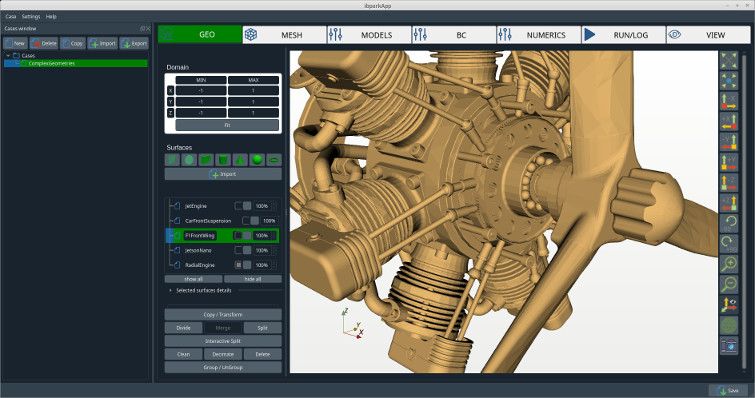

CAD Files Reader and Handler

CoGe, our advanced technology for Computational Geometry, allowed an Italian company which provides advanced Computational Fluid Dynamics simulation services, to scale up their potential super fast with a top class reliability and robustness. In this field, to support as many input file formats as possible, guarantees a strategic market advantage. For this reason, leveraging our production-ready tool which allows ingesting and to discretize NURBS files, provides a very high-value feature.