Surf Fin Hydrodynamics

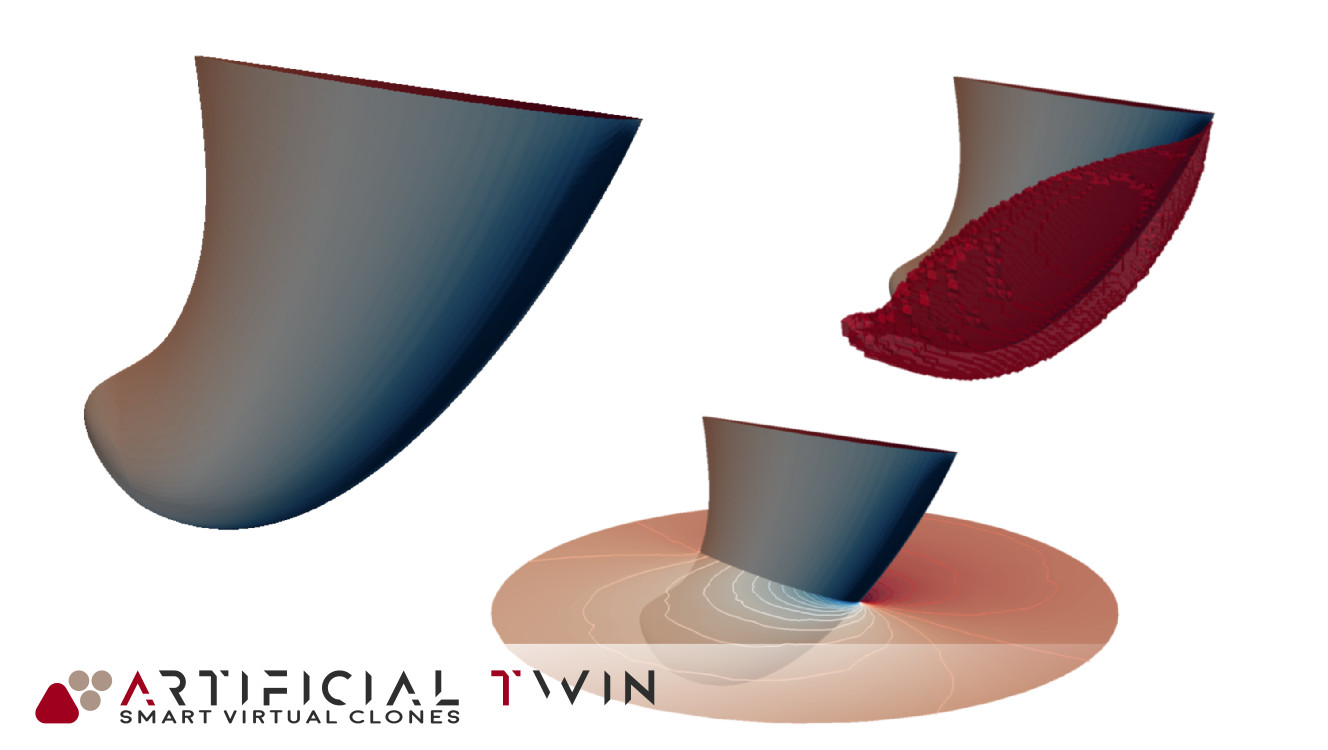

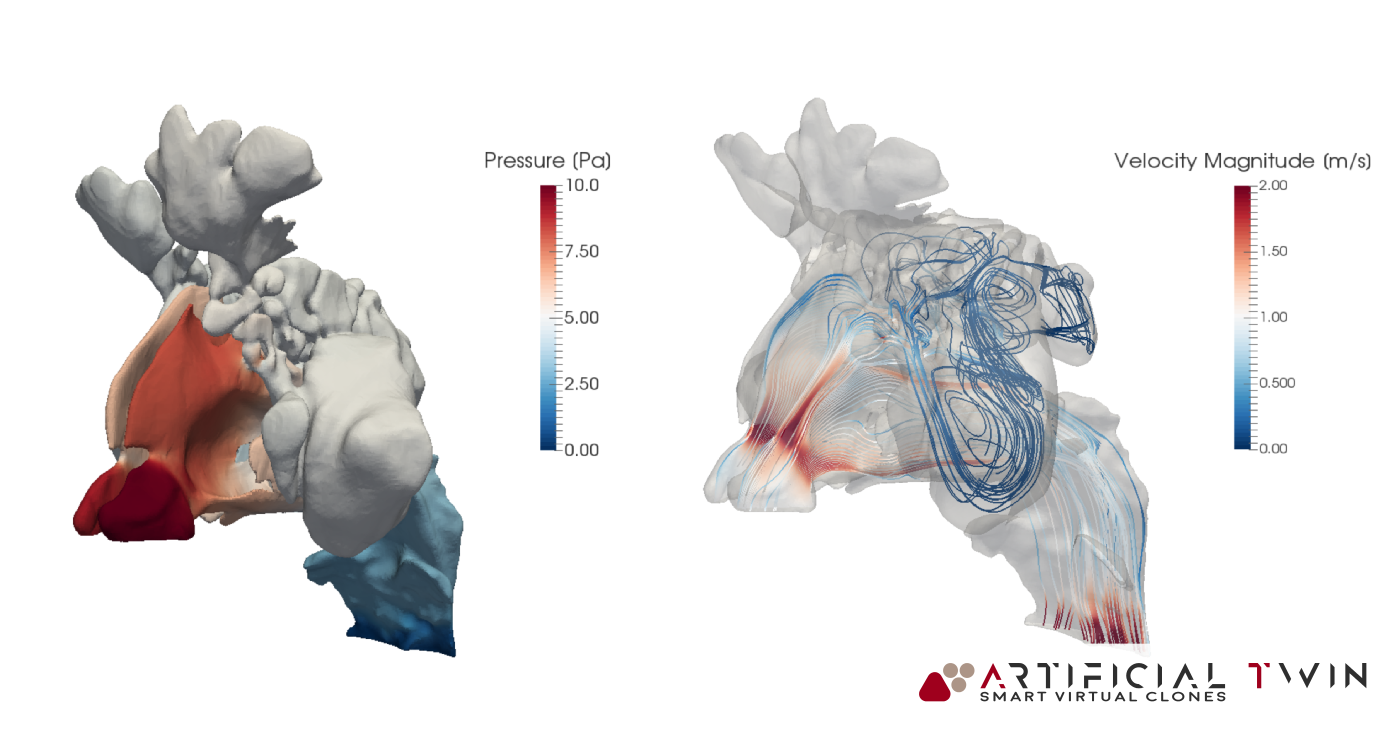

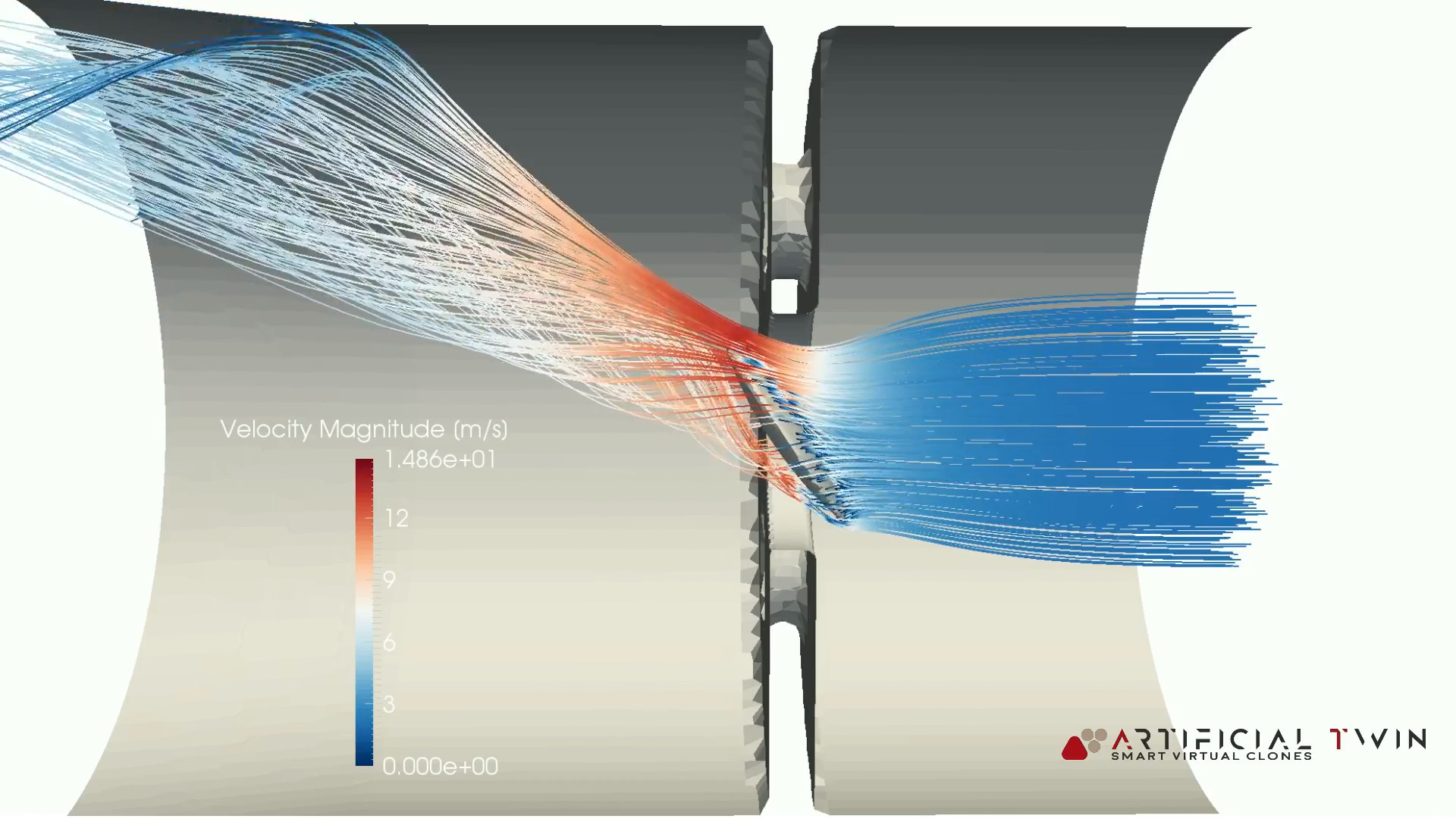

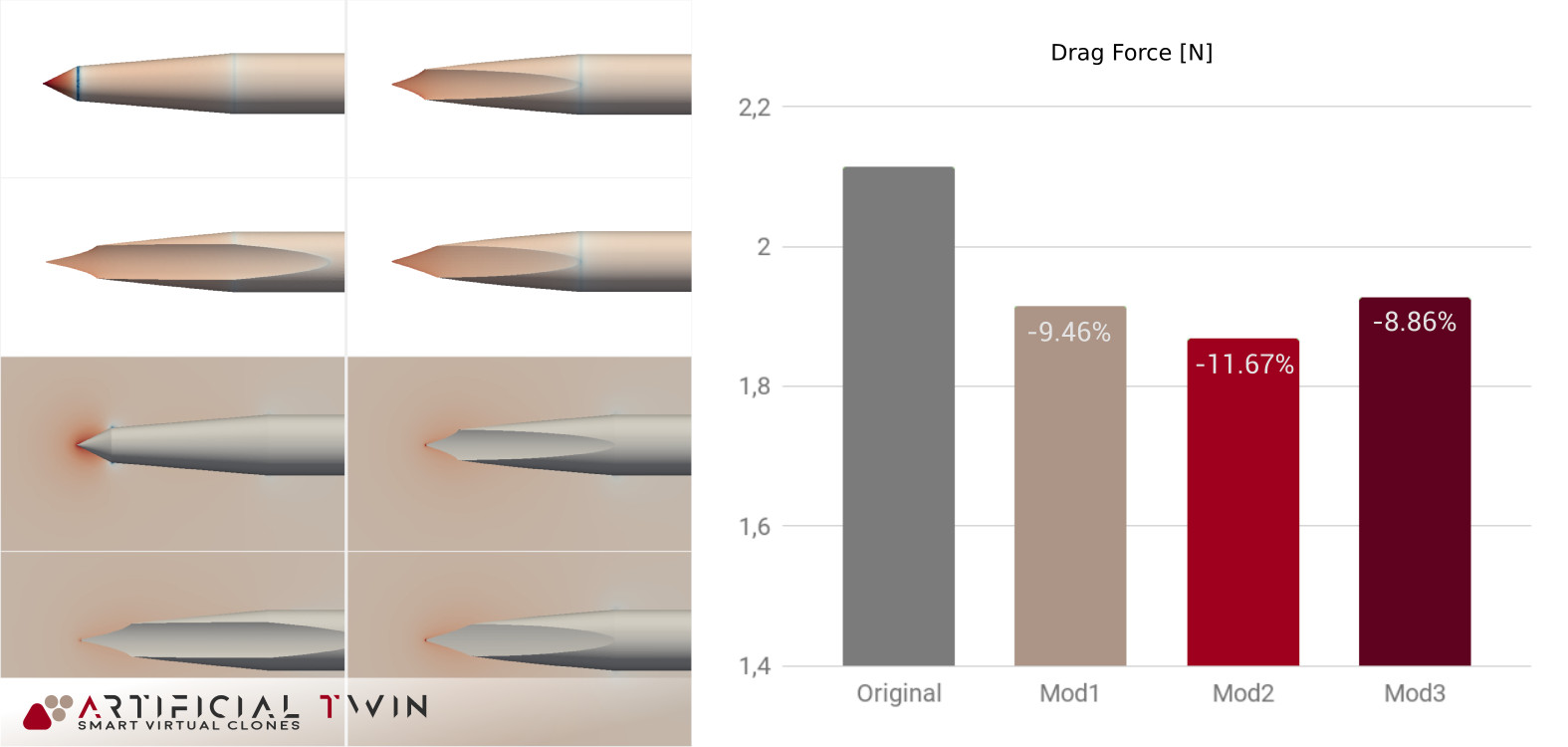

Testing prototypes, virtually PhyMo played a major role in providing guidance and consulting for Computational Fluid Dynamics (CFD) testing of several hydrofoil prototypes in a patent-pending project. The CFD results were crucial in confirming whether the humpback whale-inspired design methods were worth pursuing, allowing performance evaluation using only CAD models of the designed parts, without the need for physical prototypes. Humpback whales are renowned for their impressive maneuverability, which scientists attribute to the leading-edge bumps, called tubercles, on their pectoral fins.