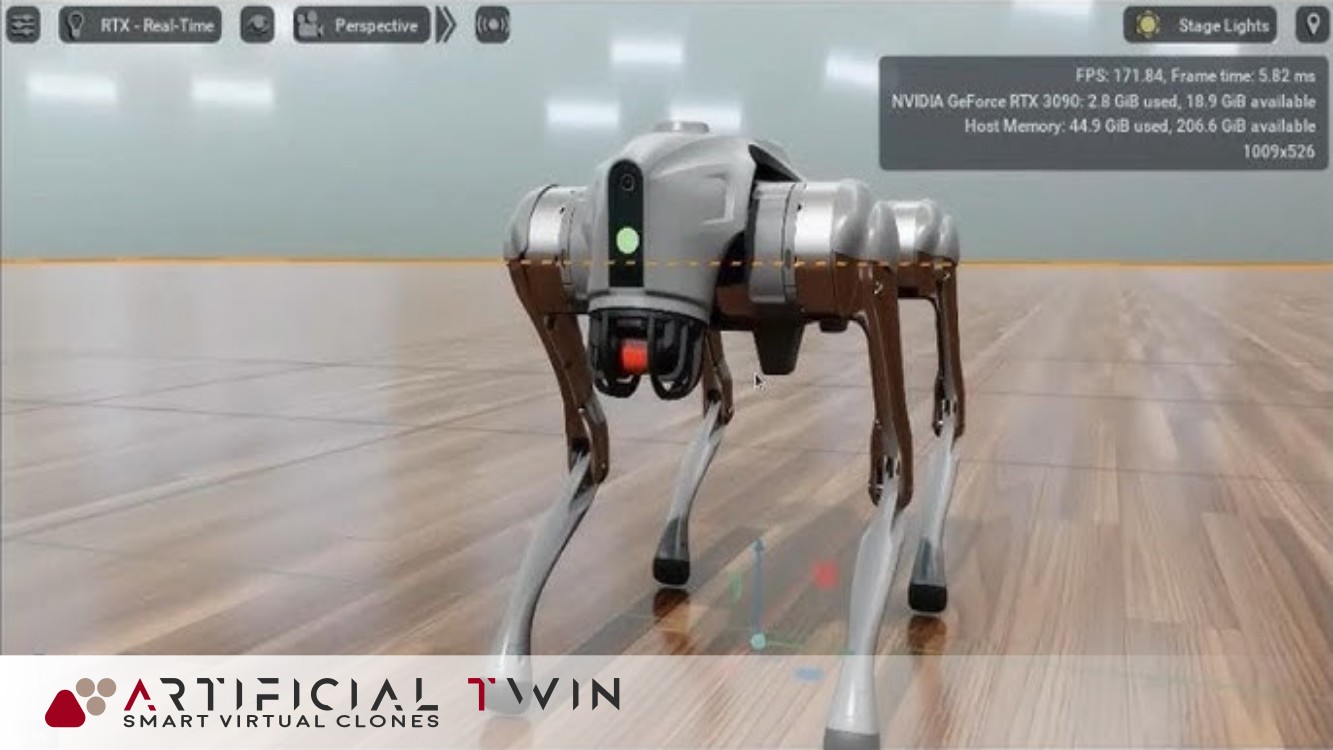

Robotics Simulation Frameworks

Cutting-edge robotics simulators enable realistic modeling of robots, sensors, and environments for testing, training, and development. Frameworks like NVIDIA Isaac Lab and Genesis provide high-fidelity physics, rich sensor emulation, and AI integration to accelerate robotics innovation. These platforms are crucial for developing spatially intelligent systems, allowing teams to iterate quickly, scale experimentation, and benchmark performance before moving to real-world deployment. Whether optimizing control policies, validating navigation logic, or stress-testing under edge conditions, these simulators form a core foundation for modern robotics pipelines.

- Physics-based simulation of articulated robots and sensors: model robotic arms, mobile platforms, and manipulators with accurate kinematics, dynamics, and sensor outputs.

- Support for reinforcement learning and embodied AI research: create rich training loops where agents learn through interaction in realistic environments.

- Integration with popular robotics middleware and AI toolkits: leverage ROS, Python APIs, and GPU-accelerated compute for seamless development and experimentation.

- Sim-to-real pipelines to transfer policies to physical robots: reduce the reality gap through domain randomization, calibration, and deployment-ready simulation fidelity.

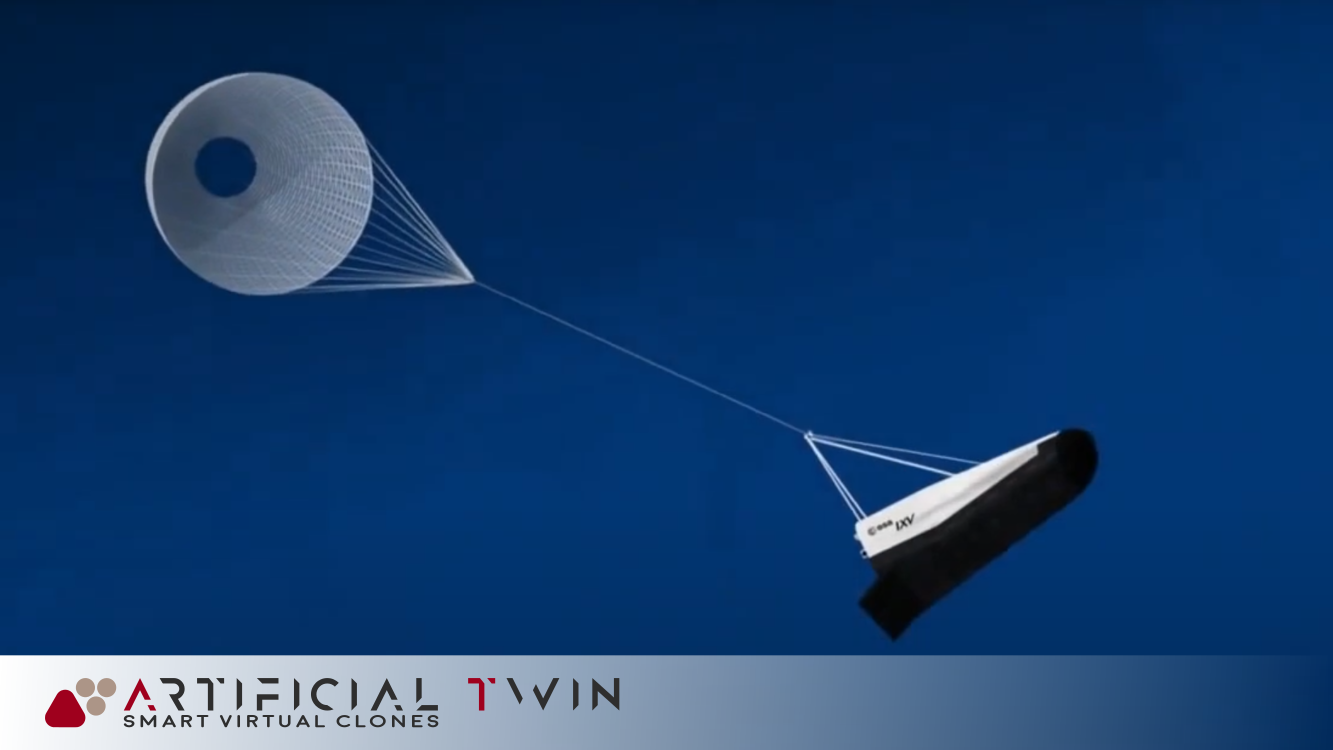

Advanced Physics Simulators

Specialized physics simulators are essential for modeling complex physical systems where traditional robotics tools fall short. Platforms like Space-Basilisk and CARLA are built to handle the intricacies of spacecraft dynamics, planetary descent, and autonomous navigation in diverse, high-stakes environments. These tools empower researchers and engineers to explore failure modes, optimize control systems, and rehearse scenarios that are too risky or expensive to test in the real world. Their extensibility and realism make them ideal for critical domains such as aerospace, defense, and automotive R&D.

- High-fidelity multi-body and spacecraft dynamics: simulate orbital maneuvers, thruster control, and attitude dynamics in near-Earth and interplanetary contexts.

- Autonomous driving simulation with realistic urban environments: test perception, planning, and control stacks in richly textured virtual cities with pedestrians, traffic, and weather variability.

- Custom physics engines tailored to client-specific scenarios: develop bespoke simulators for unique applications such as underwater robotics, ballistic trajectories, or environmental hazards.

- Support for sensor models, control algorithms, and scenario scripting: integrate synthetic lidar, radar, and cameras while defining complex decision-making scenarios for AI agents.

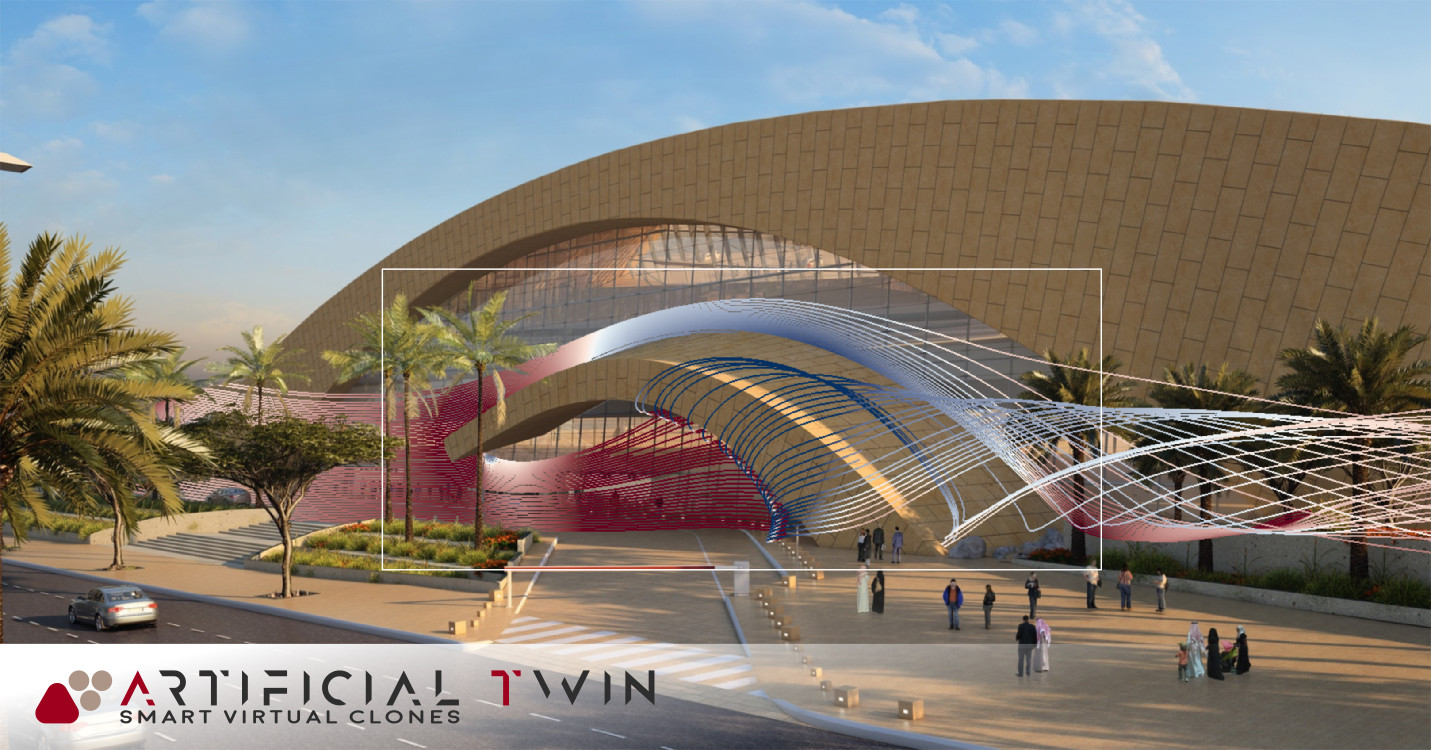

Other Simulation Domains

Simulation extends far beyond physics-based environments, encompassing diverse systems where behavior emerges from interactions, transactions, or workflows. These tools enable decision-making under uncertainty, bottleneck analysis, and scenario planning across sectors such as logistics, manufacturing, healthcare, and finance. Platforms like AnyLogic and proprietary fintech engines allow multi-scale, hybrid simulations that blend discrete, continuous, and agent-based logic to reflect real-world complexity with precision.

- General-purpose discrete-event and agent-based simulators: model systems where entities interact over time, such as supply chains, crowd movement, or epidemiological spread.

- Concentrated parameter models for thermal and process simulations: simulate heat transfer, chemical reactions, and flow in simplified yet highly controlled environments.

- Financial and economic simulation tools for scenario analysis: evaluate market dynamics, portfolio performance, or systemic risk using stochastic and game-theoretic models.

- Custom development of simulation frameworks to fit unique workflows: build task-specific simulators tightly coupled with client data, constraints, and optimization targets.

Computational Fluid Dynamics (CFD)

The CFD engine within PhyMo provides powerful virtual prototyping for analyzing how fluids interact with surfaces, structures, and internal systems. It supports steady and unsteady simulations across a variety of flow regimes and conditions. These tools help engineers and researchers iterate on designs, optimize performance, and ensure compliance with safety and environmental standards, all before physical implementation.

- External aerodynamics and hydrodynamics for lift, drag, and wake analysis: optimize vehicle shapes, marine hulls, and aerospace designs for performance and energy efficiency.

- Internal flows including pressure drop and thermo-fluid dynamics: simulate HVAC systems, engine manifolds, and microfluidic devices to refine pressure and heat profiles.

- Wind load and pollutant dispersion for urban and civil engineering: evaluate environmental impact, structural stress, and air quality in densely built environments.

- Flows interacting with solid particles, erosion modeling, and multiphase flows: handle slurry transport, cavitation, and sediment dynamics in mining, oil & gas, and environmental applications.

Finite Element Analysis (FEA)

PhyMo offers advanced FEA capabilities to evaluate the structural integrity, material response, and vibrational behavior of components under diverse operating conditions. These simulations are critical for identifying design weaknesses, validating performance criteria, and improving product durability before physical prototyping. From micro-scale materials to large mechanical assemblies, the system supports linear and nonlinear analysis workflows.

- Stress and deformation under static and dynamic loads: assess load-bearing capacity, fatigue risk, and mechanical stability under real-world forces.

- Modal frequency and shape analysis to avoid resonances: ensure safe operation by detecting natural frequencies and preventing destructive vibrations.

- Discrete Element Models for particle interaction and granular materials: simulate granular flows, powder compaction, or rock fragmentation with physically accurate models.

- Material behavior from elastic to plastic and viscoplastic regimes: capture complex deformation and failure behavior across metals, polymers, and composites.