Testing prototypes, virtually

PhyMo played a major role in providing guidance and consulting for Computational Fluid Dynamics (CFD) testing of several hydrofoil prototypes in a patent-pending project. The CFD results were crucial in confirming whether the humpback whale-inspired design methods were worth pursuing, allowing performance evaluation using only CAD models of the designed parts, without the need for physical prototypes.

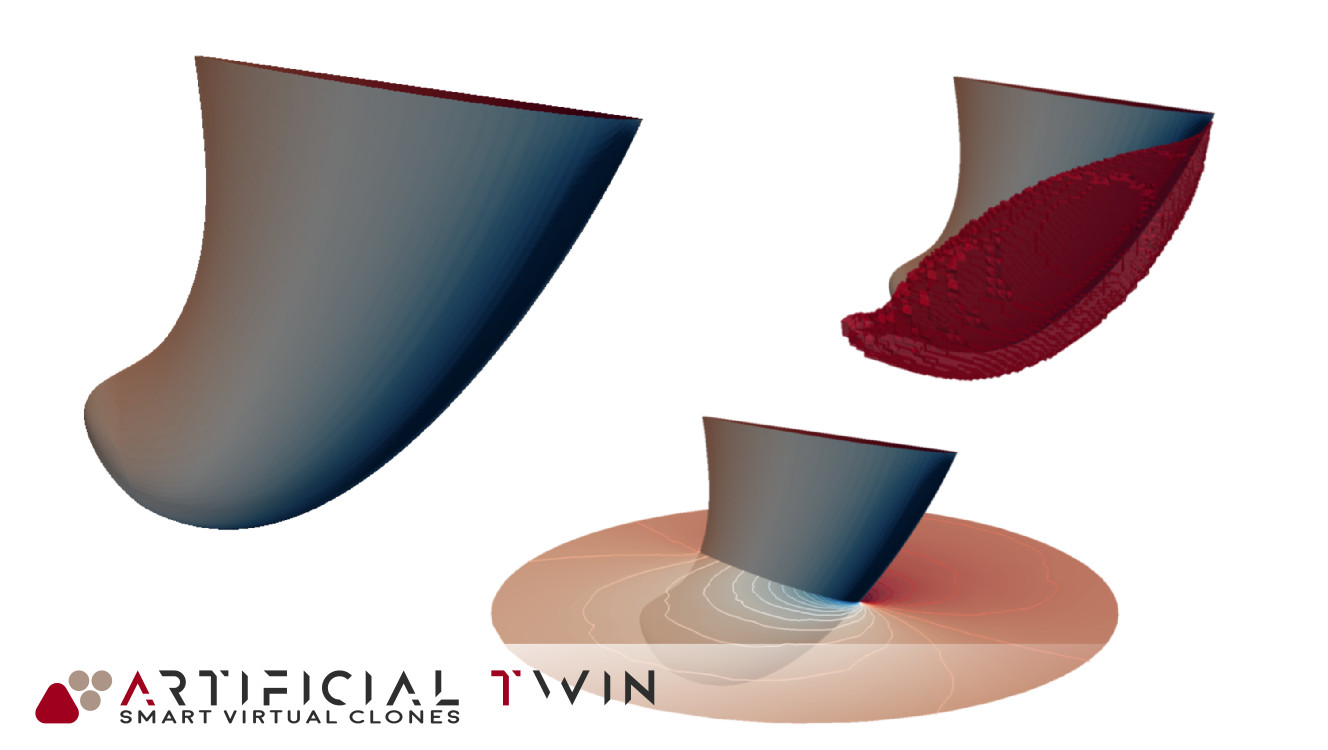

Humpback whales are renowned for their impressive maneuverability, which scientists attribute to the leading-edge bumps, called tubercles, on their pectoral fins. These tubercles are believed to delay stall and enhance maneuverability. The CFD research, directed with support from Artificial Twin, aimed to explore additional passive flow control features found on the humpback’s pectoral fin.

Three hydrofoil designs were tested at both low and high Reynolds numbers: a control with a straight leading edge, a standard tubercled leading edge commonly used in research, and a “real whale” (RW) patent-pending hydrofoil. Later, a fourth, unswept version of the RW hydrofoil was added for comparison.

Computational Fluid Dynamics simulations

PhyMo has been specialized to carry out highly accurate hydrodynamics studies on the fins, capable of calculating fundamental quantities to evaluate performance, especially: pressure distribution, wall shear stresses, lift, and drag.

For this study, the RANS equations for incompressible fluids (water in this case) with the k-epsilon turbulence model for closure were chosen. A proper computational grid with adequate wall resolution was used to ensure accurate near-wall behavior modeling. Standard boundary conditions for these contexts were adopted, together with a steady-state analysis type.

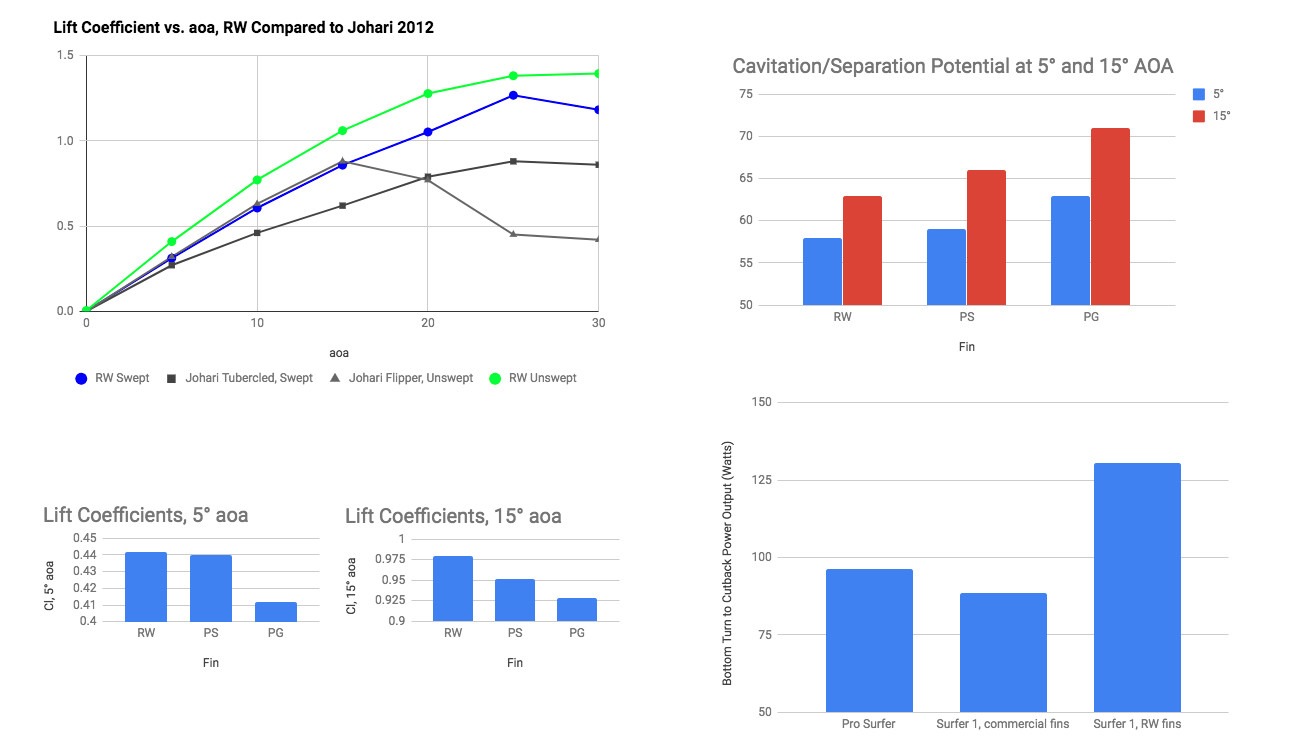

The lift coefficient results are shown below and reveal that both RW designs result in improved lift and delayed stall, when compared to the results of Johari for tubercled designs run at similar Reynolds numbers.

The CFD results obtained encouraged us to test other applications. Research results are summarized in the patent application and include promising results for RW applications as a wind turbine, tidal turbine, and surfing fin.

Validation and further analysis

Since the patent application, additional CFD studies have been conducted on high-performance surfboard fins, known as thrusters. A standard fin with a straight leading edge (PS) was compared to the RW design and to a fin with a grooved trailing edge (PG). Consistent with previous findings, the RW design again demonstrated the highest lift coefficients. The PS and PG fins were developed by Marc in het Panhuis and his research group at the University of Wollongong.

Advanced post-processing of wall shear stresses enabled identification of areas with potential for cavitation on the fin surface. A custom “cavitation/separation potential” metric was developed, showing that the RW fin had the lowest risk of cavitation or flow separation.

The CFD results for thruster fins are being validated with prototypes and data collected using a Trace sports tracking device. Preliminary findings indicate a 35% increase in turning power for a surfer using the RW fin compared to a professional surfer, and nearly a 50% increase compared to the same surfer using standard commercial fins. Power calculations followed the methods described in Gately et al., 2017.

Validating our CFD results with field tests provides robust verification of the designs, offering greater confidence than CFD or field testing alone. Additionally, CFD analysis helps us identify and address potential issues in complex RW designs, enabling improvements for future applications, such as drone propellers, before physical prototypes are built.

Specific needs, carefully accommodated

Every project comes with its own specific constraints, which can involve a wide range of aspects: available budget, the quantity and quality of information about the phenomena of interest, timing requirements, intellectual property considerations, operating system compatibility, or the need for highly specific post-processing outputs.

In a context involving patent-pending technology like this one, many of these needs are especially relevant. The success of this collaboration strongly reflects one of the main goals of Artificial Twin: to provide dedicated solutions that accommodate every customer’s requirements, making their work as smooth as possible and helping them achieve all their