A key factor for 3D printing pricing

More and more platforms offering 3D printing services are appearing online. Their workflows are fairly standard: the user logs into the platform, uploads a 3D model (in a compatible format), selects operations (e.g. scaling) and features (e.g. material or surface finish), and finally proceeds to payment to complete the order.

Defining an accurate pricing algorithm is vital for these companies, as they operate with narrow margins and face increasing competition. A pricing strategy that’s too low leads to financial loss, while one that’s too high can drive customers away.

Pricing usually depends on multiple factors, from printing material and surface finish to shipping method and material volume. Among these, a crucial yet lesser-known factor is the so-called "Machine Space," which becomes easy to understand once clearly explained.

In this success story, CoGe was tailored to address this specific need for WOMP, a New York-based 3D printing service provider. It now runs live in their production environment, calculating the "Machine Space" (and other geometrical features) for 3D models within a few seconds of upload.

The Machine Space

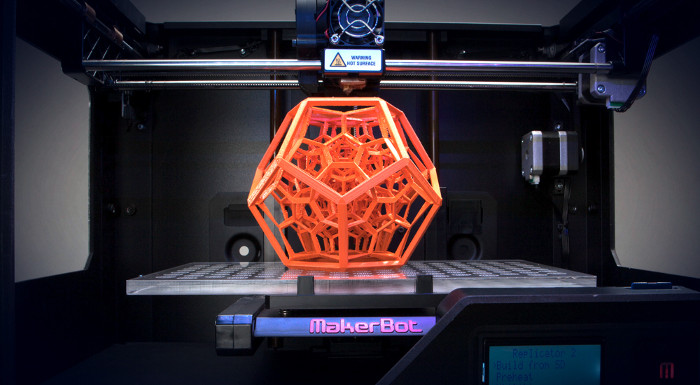

Every 3D printing service provider needs to optimize the printing process to reduce costs. A common strategy involves grouping the right objects to print together, maximizing use of the printing space while maintaining sufficient clearance between parts to ensure feasibility.

To understand how much space a part occupies, two main factors must be considered. First, to ensure sufficient clearance, a minimum 1 mm offset from the original object must be added. Second, and more subtle, small holes below a certain threshold prevent placing other objects inside the model’s volume. As a result, the volume truly occupied becomes its 3D "convex hull," based on the already-expanded geometry.

Pricing usually depends on multiple factors, from printing material and surface finish to shipping method and material volume. Among these, a crucial yet lesser-known factor is the so-called "Machine Space", which becomes easy to understand once clearly explained.

Together, these considerations define the so-called "Machine Space", a critical input in determining the cost of a 3D-printed part. Being able to evaluate it accurately, across models of varying shapes and sizes, is essential to developing an effective pricing strategy.

How CoGe Machine Space algorithm works

From a technology standpoint, CoGe processes input in three steps, after reading and storing the polygonal mesh.

First, it expands the original model’s volume by applying a 1 mm offset. This step is particularly complex on polygonal meshes and can involve topological changes, such as vanishing vertices/faces/triangles or surface intersections, making it a delicate operation that demands careful handling.

The second step removes all regions of the space that are inaccessible from the exterior, based on the specified hole-size threshold. This is the most challenging phase. Multiple strategies exist, each offering trade-offs between robustness, speed, and accuracy. CoGe uses a parallel algorithm delivering top-tier robustness and accuracy, handling meshes with up to 6 million triangles in under 60 seconds.

Once the expanded volume and valid domain are computed, the final step is to measure the occupied volume. Again, multiple strategies are possible. CoGe implements a parallel algorithm that balances speed, accuracy, and robustness effectively.

From development to deployment, an all-inclusive solution

At Artificial Twin, we’re committed to providing tailored solutions for our clients. Often, this includes seamless integration into their production environments once development is complete. That’s exactly what we delivered for this project: our expertise in Cloud Computing (AWS, Google Cloud, Microsoft Azure) enabled us to support the WOMP IT team in selecting the right instance and setting up the environment with all necessary software.

As a result, our dedicated CoGe application was deployed live in just a few minutes, ensuring smooth adoption and sparing our client any operational overhead.